Story by James Bennett – The Daily Herald

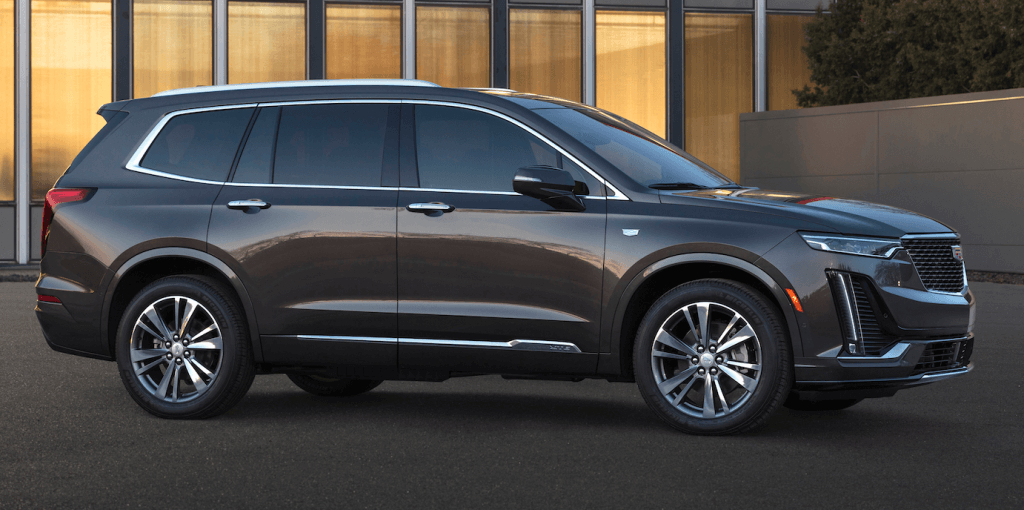

General Motors has given a green light to the Cadillac XT6 for full production.

The three-row SUV rolled off the assembly line at the Spring Hill Manufacturing Facility for the first time Friday and should arrive in dealerships soon, likely priced around $53,000.

“It’s a landmark moment — a milestone for us,” Plant Manager Ken Knight said Tuesday as he invited The Daily Herald to test drive the XT6 and watch it move through the assembly line. “We’ve gotten really good at product launches. Every launch is a little different, but we’re seeing fewer and fewer problems that our design engineers need to fix after our tests and during production setup because of computers and 3D modeling. Practice makes perfect.”

Through the years, local workers have produced millions of engines, cars and SUVs in Spring Hill, starting with Saturn in 1990 and later including the Traverse and Equinox. The XT6 became the fourth vehicle being produced simultaneously now in Spring Hill, joining the Cadillac XT5, GMC Acadia and Holden Acadia in the lineup.

“One of our core competencies in the Saturn days was launching new products,” United Auto Workers Local 1853 Chairman Mike Herron said. “When we say, ‘We’re great at product launches,’ it’s because we have the ability to produce anything that General Motors gives us — now or in the future — right here in Spring Hill with a quick turnaround.

“We are in an auto market currently in which change is a constant,” he added. “Customers want upgrades. They want the best technologies. We can’t produce cars that no one wants and have the company write them off. We have to be committed to world-class excellence with the Cadillac name on it.”

Spring Hill managers and team leaders knew the XT6 was coming to Spring Hill about two years. The Daily Herald was first to report in April 2018 that the XT6 would be manufactured here. The XT6 was unveiled at the Detroit Car Show in January, and GM CEO Mary Barra visited Spring Hill later in the month. Cadillac President Steve Carlisle saw the progress in person in April.

“We have been training our people to make them,” Knight said, explaining what happened after Barra and Carlisle left. “We have a system where everyone has a primary job and a secondary job. Then that expands quickly as the cars start down the line. All of the people in the building know how to make them now, not just the 20 or so people on the initial launch team.”

Launch Manager Brian Cross supervised the XT5 and GMC Acadia as they ramped up to production. The 20-year GM veteran said he focused on the attention to detail.

“We wanted to make sure the quality of design was set for the employees on the floor,” Cross said. “We wanted the quality to be what was expected by our customers. It’s going to be a really exciting product for the market.

“The process brought a combination of excitement and stress,” he added. “Every launch has last-minute fixes that have to be put into place, and thousands of details have to come together for the launch to be successful. It’s exciting to watch something you have watched for several years to come to fruition.”

UAW team leader James Hobgood spent hundreds of hours across three shifts, training employees. He said he noticed few unexpected hiccups in the development process.

“By planning ahead, we were able to absorb and fix any last-second glitches,” said Hobgood, whose group focused on the instrument panel line. “I worked with many different employees on an individual basis and showed them what they needed to do. I wrote good, clear job instructions so they can go build quality cars.

“I was looking for what the operators needed to make their job easier,” he continued. “Maybe it was more training. If they were struggling on a job, I evaluated if they just needed a little more time and attention of if their job needed to be set up differently.”

Team leader Craig Moore said workers on the line were ready when it was time to make the new vehicle. One minute, a worker is painting or trimming an XT6. The next, it could be an Acadia Holden.”

“It becomes second nature,” Moore said. “You can look at a car and look at a manifest and know exactly how to build that car.”

After cars have completed the 24-hour assembly process, they’re ready for final approval. At least two of each vehicle go a bumper-to-bumper audit, inside and out. The inspection, with along checklist, takes about four hours for each.

“We’re the voice of the customer. We’re supposed to look at the vehicle like the customer would,” said Jay Richez, a 34-year GM employee who works in Global Customer Audit. “The XT6 is doing well so far. We’re getting really familiar with it. I have inspected three or four myself.

“XT6 is going to be a great seller,” he predicted. “I say that based on the options it has and the finishes it has. It’s a great value.”

Herron said workers have done “a fantastic job with these products” and were willing to learn new things, whether it was a Cadillac or even an electric or hydrogen car, if that’s what GM wanted to produce in Spring Hill.

“Five years ago, we did not know what we were building. But we knew there was a commitment to building something,” Herron said. “We have worked hard. We’re proud to have products to support our jobs and economic prosperity in this region.”

After adjusting for the XT6, the plant will take a short breather before preparing for 2020 models of the XT5 and GMC Acadia.

“There will be changes, a lot of it will be under the skin — technological things, control systems, transmissions,” Knight said. “The Acadia visually will look quite different.

“There was a chance the XT5 and Acadia would get overshadowed a bit with the new XT6. We could not let that happen. Now the XT6 is out of the barn. In August, we will adjust for the new XT5 with the Acadia to follow.”